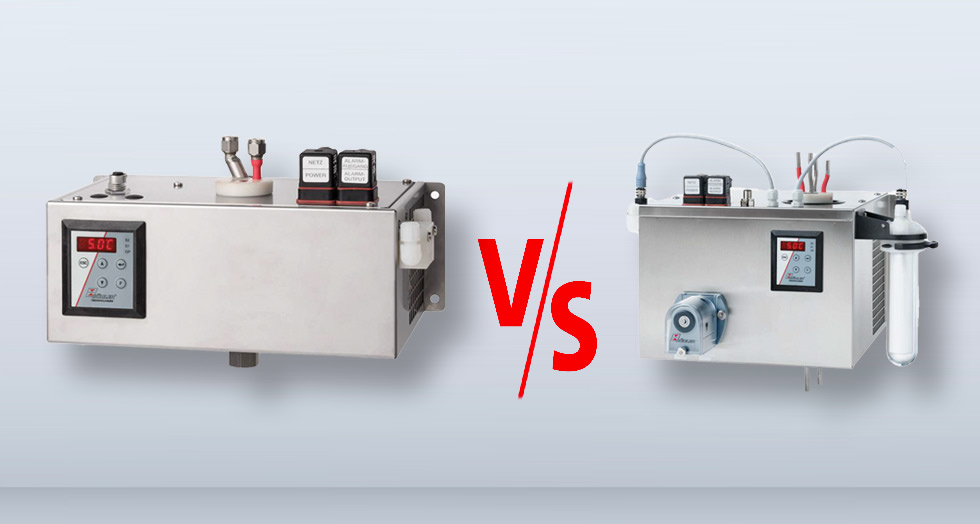

Peltier versus compressor cooling system

Each principle has its strengths

In extractive gas analysis, compressor gas coolers are used in addition to thermoelectric (Peltier) sample gas coolers, especially for higher performance requirements.

In all cases, it is particularly important that the desired dew point is reliably and precisely maintained so that the sample gas enters the analyser free of moisture.

Among other things, maintaining the dew point is strongly dependent on the operating and ambient conditions of the analyser system. This is physically due to the fact that sample gas coolers can only provide a system-related cooling capacity, but the cooling result is determined, among other things, by the prevailing ambient temperatures. Thermoelectric systems use semiconductor elements which generate a heat gradient by applying electric current. If, for example, a hot stream of sample gas is led past the element, the heat is extracted from the gas and dissipated to the ambient air via a heat sink on the other side. The cooling capacity of this type of cooler is determined by the size and current consumption of the Peltier element, the efficiency of the heat sink and its exposure to the ambient air and its temperature.

The cooling system of a compressor sample gas cooler corresponds to that of a refrigerator. Here, the size of the compressor and the recooling capacity of the heat exchanger determine the cooling capacity. Sample gas coolers of this type are particularly suitable for multi-line measuring systems and large fluctuations in ambient temperature. The Bühler constant control system increases the energy efficiency of our compressor coolers.

Both series have cooling blocks with exchangeable heat exchangers. This offers enormous flexibility of use.